In the modern power system, the power distribution room plays a vital role. It is the core node connecting power generation, transmission, transformation and power consumption. Its safety hazards cannot be ignored.

The distribution room contains a large number of electrical equipment and dense cable lines. Once an electrical fault occurs, it may cause a fire accident. Electrical fire is one of the major safety hazards faced in distribution rooms.

For important facilities such as power distribution rooms, real-time monitoring of temperature and humidity is very necessary, because high temperature and humidity will lead to reduced performance of electronic components, shortened service life, and reduced insulation performance. High temperatures can also cause abnormal downtime of servers in the power distribution room. In serious cases, it may even cause the risk of electric shock or explosion.

Distribution room temperature and humidity specifications:

· The temperature of the low-voltage switch cabinet is 15 degrees and the humidity is below 75%.

· The temperature of the high-voltage switch cabinet is 25 degrees and the humidity is below 50%.

· The low-voltage switch cabinet in the power distribution room adopts the standard of GB7251.1-2005.

· The power distribution room is a 10KV high-voltage switch cabinet that adopts the GB3906-2006 standard.

Why monitor temperature?

Prevent overheating and fire risks: The electrical equipment in the power distribution room will generate heat during normal operation. If the heat dissipation is poor or the load is too high, the internal temperature of the equipment will continue to rise. In severe cases, it may cause overheating of electrical components, insulation aging, and short circuits. Even caught fire.

Excessive temperature will affect the performance and life of electrical equipment. For example, transformers, switch cabinets, circuit breakers and other equipment have their own designed operating temperature range. Exceeding this range may cause equipment damage or malfunction.

Why monitor humidity?

Moisture-proof and insulation failure: In a high-humidity environment, moisture in the air can easily condense inside electrical equipment, especially on insulating materials, which may lead to a decrease in insulation performance, leading to safety accidents such as leakage and short circuits.

Avoid discharge and arc faults: Humid air will increase the breakdown strength of the air medium and increase the risk of electrical gap discharge. Especially in high-voltage switch cabinets, excessive humidity may cause arc flashover, endangering the safety of equipment and operators.

Prevent electronic components from getting damp: High humidity can easily cause electronic components to fail due to moisture, affecting the normal working performance of the equipment and shortening its service life.

The secret weapon for real-time monitoring of temperature and humidity in distribution rooms

The method of realizing real-time monitoring of temperature and humidity in distribution rooms generally uses Internet of Things technology. The specific solutions are as follows:

Install temperature and humidity sensors in the distribution room

During installation, temperature and humidity sensors are generally placed in key areas, such as equipment-dense areas, areas with high heat generation, air inlets, air return vents, etc., to ensure that they can accurately reflect and control the environmental conditions of the entire computer room. The sensor can collect temperature and humidity data in the environment in real time and convert these data into electrical signals.

Data transmission

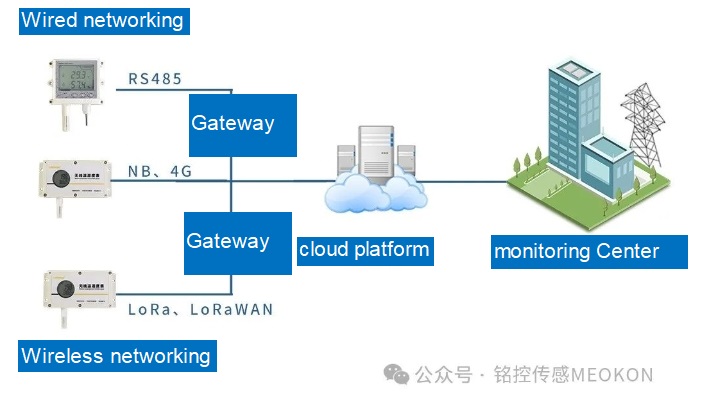

Upload the temperature and humidity data collected by the sensor to the background monitoring system through wired (such as RS485 bus) or wireless (such as LoRa, LoRaWAN, NB-IoT, 4G, etc.) methods.

|

|

Backend monitoring system

Receive and process the data uploaded by the front-end sensor for real-time display, storage and analysis. When the temperature and humidity exceed the preset threshold, an alarm signal can be automatically sent out so that timely measures can be taken to adjust the temperature and humidity environment in the power distribution room.

Mobile APP/computer remote viewing

Managers can check the real-time temperature and humidity conditions of each power distribution room at any time through the mobile APP or computer to achieve remote intelligent management.

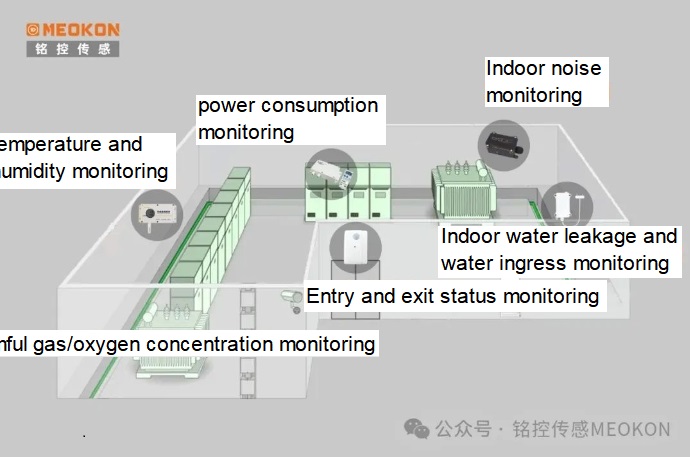

Temperature and humidity monitoring in distribution rooms is only part of ensuring the stable operation of the power system. It is also necessary to monitor and manage the operating status of distribution equipment. Through real-time monitoring of various electrical parameters and environmental factors, safe and efficient management of distribution facilities can be achieved.

- Remote real-time monitoring of sensing equipment, reducing the difficulty of manual inspection.

- Automatic fault alarm to ensure stable operation of power equipment and reduce fault losses and operation and maintenance costs.

- After the data is collected and transmitted to the environmental control system, the working status of air conditioners, dehumidifiers and other equipment can be adjusted according to actual needs to achieve precise control, thereby achieving the purpose of energy saving and emission reduction.

- Effectively reduce equipment failure rates caused by environmental factors, extend equipment service life, and reduce operation and maintenance costs.

Post time: Jan-26-2024