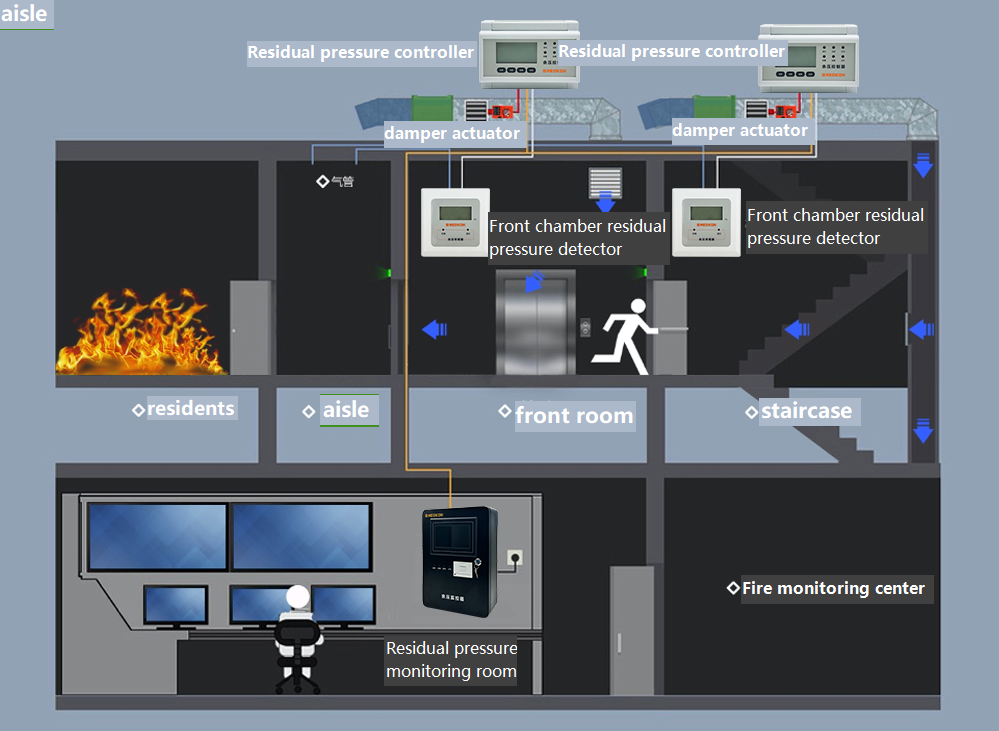

In modern high-rise buildings or large public facilities, when a fire occurs, in order to ensure that people can escape smoothly, mechanical pressurized air supply and smoke prevention and exhaust systems are usually installed, especially in smoke-proof stairwells and front rooms, refuge floors, Key parts such as fire elevator front room.

When a fire occurs, the residual pressure monitoring system will be activated to provide positive pressure to the relevant space through the fan, forming an environment with a higher pressure than the outdoor or fire source area to prevent smoke from invading these important evacuation channels. Reduce the harm of smoke to personnel and ensure the visibility of evacuation passages; ensure that personnel can identify evacuation paths as soon as possible and evacuate safely to maximize the protection of personnel’s lives.

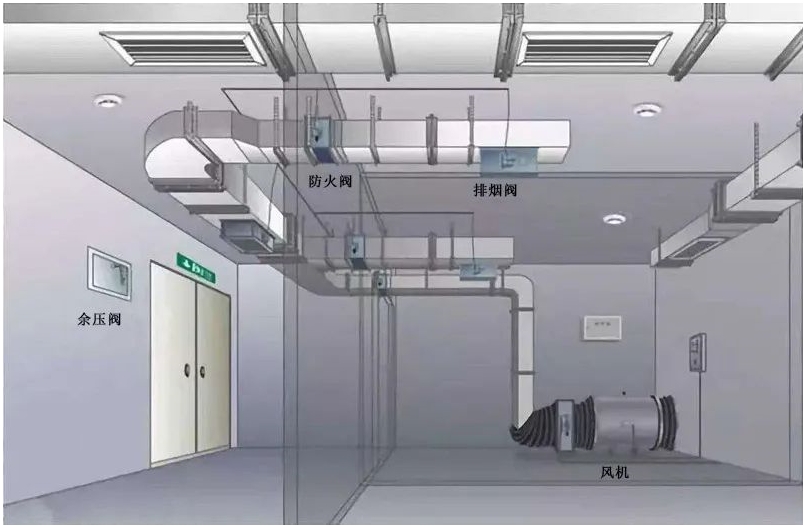

What is a smoke prevention and exhaust system?

The smoke prevention and exhaust system is a combination of the smoke prevention system and the smoke exhaust system.

Smoke prevention system: Use natural ventilation to prevent fire smoke from accumulating in spaces such as stairwells, front rooms, and refuge floors (rooms), or use mechanical pressurized air supply to prevent fire smoke from invading stairwells and front rooms. , refuge floor (room) and other spaces.

Smoke exhaust system: A system that uses natural smoke exhaust or mechanical smoke exhaust to exhaust fire smoke in rooms, walkways and other spaces outside the building through dedicated smoke exhaust ducts and smoke exhaust fans.

<<Technical Standard for Building Smoke Prevention and Exhaust Systems GB51251-2017>>

3.4.4

The mechanical pressurized air supply volume should satisfy the increasing pressure distribution from the corridor to the front room to the stairwell, and the residual pressure value should meet the following requirements

1) The pressure difference between the front room, the closed refuge floor (room) and the walkway should be 25Pa-30Pa;

2) The pressure difference between the stairwell and the walkway should be 40Pa-50Pa;

Meokon provides a series of smart sensor terminals for the residual pressure system to monitor the residual pressure changes in the evacuation passages of each floor in real time. It mainly controls the air supply volume of the positive pressure air supply fan. In the event of a fire, it ensures that the residual pressure in the stairwell and front room is within Within a reasonable range, smoke cannot enter when personnel are evacuated.

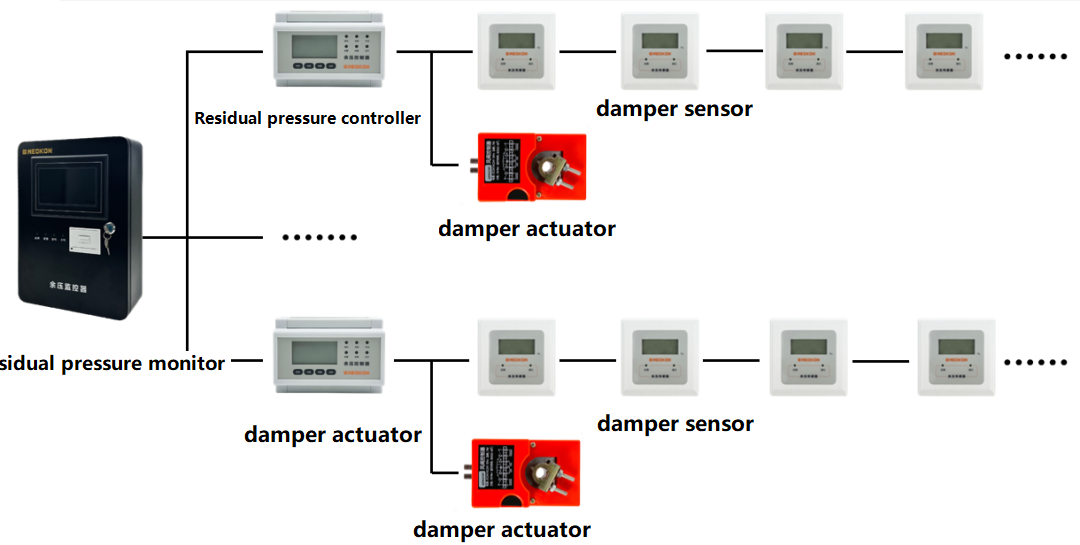

01 Residual pressure monitor

The product uses a 7-inch touch screen for interaction and is installed in the fire control center. It accepts alarms and fault signals from the residual pressure controller, status signals from the damper actuator and data from the residual pressure sensor in real time, and provides real-time data display, audible and visual alarms and other functions. It is convenient for managers to fully grasp the residual pressure status of the entire building and take quick measures in case of emergency. (Can manage up to 254 residual pressure controllers.)

Features:

Adopting non-polar two-line bus communication, it is stable and reliable, and the communication supports up to 2000 meters.

It has strong load capacity and can manage up to 254 residual pressure controllers.

It is powered by conventional power supply and can also be powered by a large-capacity battery for emergency battery life.

It uses a 7-inch touch screen for interaction and supports wall-mounted installation.

02 Residual pressure controller

The product is installed in the fan control cabinet, receives and processes data from each residual pressure sensor, judges the pressure difference beyond the set range, and issues instructions to the actuator according to the situation to adjust the working status of related equipment. (Can manage up to 64 residual pressure sensors and 1 damper actuator.)

Features:

It adopts non-polar two-line bus communication, which is stable and reliable. The communication supports up to 2000 meters. It adopts sound, light and display alarm methods, and the screen displays alarm information.

When the value of the residual pressure sensor exceeds the limit, the air valve actuator is automatically linked to release the pressure.

It has strong load capacity and can manage up to 64 residual pressure sensors and 1 damper actuator.

03 Residual pressure sensor

The product uses an LED display to display the residual pressure value in real time. It is installed at the entrance of areas where residual pressure needs to be maintained, such as smoke-proof stairwells, front rooms, etc., to measure and feedback the pressure difference between the area and adjacent spaces in real time. .

Features:

It adopts non-polar two-line bus communication, which is stable and reliable, and the communication supports up to 2000 meters. It uses a differential pressure sensor to measure pressure and an LED display to display the residual pressure value in real time. It adopts two bus power supply, and the power supply voltage is DC24V. There is no need to pull additional power cords. It uses DIP switches to set the slave address and alarm value, which is simple and convenient.

04 damper actuator

Installed on the bypass pressure relief pipe, when the residual pressure exceeds the set value, the residual pressure controller will issue instructions, and the air valve actuator controls the corresponding pressure relief valve to open or close, thereby adjusting the pressure level in the space.

Post time: Apr-22-2024